Irvine, CA (PRWEB)

June 24, 2015

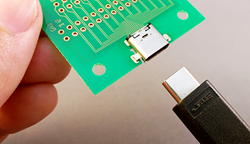

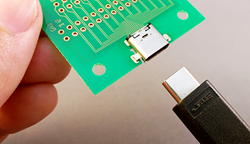

JAE, a global manufacturer and marketer of connectors, user interface solutions and aerospace electronics, has debuted a full line of USB Type-C™ connectors. Based on the USB 3.1 specification that defines the next generation of USB connectors, the JAE DX07 offers all of the features this new standard has quickly become known for, including:

Small form – The ultra-compact DX07 is just slightly larger than the micro USB 2.0 connectors used in most of today’s phones

High speed data transmission – At 10 Gbps, the USB 3.1 Type-C™ connector is one the fastest small form connectors on the market

Power – Up to 100W

Reversible design – Users can connect in either direction; no more frustration, eliminates potential for damaging connector.

Going forward, the USB Type-C™ connector will truly be universal – the one USB connector that can be used for everything. For example, today’s big devices use standard USB connectors, and smaller devices, such as mobile phones, use Micro USBs. Ultimately, though, all devices – large and small – will use the USB-C connector. As one of the first companies to introduce a complete line of Type-C™ connectors, JAE expects to remain at the forefront of its ongoing development.

“We were one of the first interconnect companies invited by the USB-IF to participate in the development of the USB Type-C™ connector,” said Glenn Griffin, Vice President of JAE Electronics. “As such, our people know first-hand the enhanced capabilities offered by this new standard and we at JAE are truly excited to be one of the first connector companies in the world to offer a full line of USB Type-C™ connectors.”

Other important features of the new USB Type-C™ connector embodied in the new JAE DX07 connector family include:

Friction lock equipped – The friction lock is housed inside of the connector and not exposed or visible to the environment. This presents a much cleaner looking plug/cable connector since there are no holes cut in the shell or protruding lock springs.

Reduction of EMI – Ground spring contacts, specifically designed to connect the plug and receptacle shells, substantially reduce the level of EMI.

Supports power delivery (3A / 5A) – While all USB connectors facilitate power delivery, most legacy connectors require some modification to do so. Type-C™ connectors, on the other hand, can transmit a higher current without any changes or modifications. That’s because with Type-C™ connectors, the power is divided over several contacts, 4 for power and 4 for power return/ground, unlike legacy USB connectors which always use a single pin/contact for power.

Future developments for the USB Type-C™ connector include adding the capability to support alternate modes of information; for example, connecting audio the same way a 3.5mm jack currently does on a phone or tablet or sending video over the connector such as DisplayPort. Ultimately, the goal is that a single Type-C™ USB port on a device will able all connection needs.

According to the USB-IF shipments of USB 3.0 and 3.1-enabled devices will hit 2.1 billion units in 2016, up from 684 million units in 2014. Type-C™ connectors will be featured on 12% of mobile handsets by 2016; that is according to a recent report by Strategy Analytics.

For more information on JAE Electronics and its new DX07 family of USB Type-C™ connectors please visit http://www.jae.com or check out the DX07 Series Product Introduction animation video.

About JAE Electronics

Japan Aviation Electronics Industries, Ltd. (JAE), designs, manufactures and markets electronic components, fiber optic connectors, LCD monitor connectors, waterproof electrical connectors and other digital systems. A global company, JAE is a recognized leader in providing solutions to complex design requirements. By combining divergent technologies from experience gained in the aerospace industry, JAE has been able to transfer these technologies into advanced connector designs. From connectors on Japan’s Bullet Train, to the smallest hand-held video camera, JAE continues to meet the most demanding applications in the industry.